Sage 50 Bill of Material

I wanted to provide you with the process below which I think will help clarify how Sage 50 assemblies work. Hopefully this will be enough information to test thru the process with me or your team. The reason for my suggesting you walk thru this is to see the effort required to manage multiple level bill of materials.

When using multiple level bill of materials Sage 50 does not have the capacity to help you manage processes like scheduling, timing of demands for inventory items or shop floor routing and scanning capabilities. I bring these points up to confirm whether or not you might need those now or in the future to help your day to day operations become more efficient.

Sage 50 Bill of Material by Sage Software

Sage 50 can do multiple level bill of materials. Most often the challenge is that each sub assembly needs to be completed One at a time Before the final assembly can be completed and invoiced. Sage 50 does not have a back flush feature to allow

You to have clients request a delivery date and then manage the purchase order or build process to calculate the needed start date.

That said Sage 100 will step up to those needs. I can get a demo set up for this application so you can see the difference. The only conflict I am aware of in running Sage 50 and Sage 100 on the same serve is a potential conflict in the versions Of crystal reporting.

Discovery

Once we have a discovery call on Sage 100, I can then pull together pricing. If you wish I can get this on our schedule and we can offer estimates of conversion. We have migrated many clients in similar positions.

Yes, you can have some folks on Sage 50 and Some on Sage 100. A Consideration would be consolidated financials If you are doing that now using Sage 50 consolidated financials. That said Sage Intelligence may be able to provide this with a bit of setup. During the initial discussion we can him his opinion of Sage Intacct which may be Another option.

Let me know how you want to proceed. I am here to help. 800-475-1047

This is the process To set up inventory items

Set up all raw materials as inventory item class “stock”

Example of stock item is PTWheel-6

Set up all sub-assemblies as inventory item class “assembly”

Example of sub-assembly is PTHANDLE-ASM

Set up finished item – as inventory item class ‘assembly”

the components could be raw materials and/or sub-assemblies

Example of finished item is Red Lawn Mower

| Item ID | Item Description | Qty Needed | Qty on Hand | Est Cost |

| Red Lawn Mower | Red 18″ Reel Mower w/Tracking | |||

| . PTHANDLE-ASM | 4′ Handle Assembly | 1.00 | ||

| . . PTHANDLE-BENT4 | Handle – 4 ft bent | 2.00 | 150.00 | 13.18 |

| . . PTBOLT-1.5 | Hex bolt 1.5″ | 4.00 | 1,280.00 | 1.32 |

| . . PTNUT- 5/16 | Hex nut 5/16″ | 8.00 | 1,180.00 | 0.56 |

| . . PTBOLT-2 | Hex bolt 2″ | 4.00 | 900.00 | 1.36 |

| . PTWHEEL-6 | 6″ Wheel | 2.00 | 70.00 | 12.00 |

| . PTWHEEL-10 | 10″ Wheel | 2.00 | 70.00 | 16.00 |

| . PTBLADE-99-9 | 16″ 5 blade | 1.00 | ||

| . . PTBLADE-16-5 | 16″ 5 blade | 1.00 | 56.00 | |

| . . PTNUT- 5/16 | Hex nut 5/16″ | 6.00 | 1,180.00 | 0.42 |

| . PTBOLT-1.5 | Hex bolt 1.5″ | 6.00 | 1,280.00 | 1.98 |

| . PTNUT- 5/16 | Hex nut 5/16″ | 6.00 | 1,180.00 | 0.42 |

| Red Lawn Mower Total | Cost | 103.24 | ||

In this example the highlighted items in orange are the sub-assemblies – this is the report found at

Reports – inventory – bill of materials

In the items that are sub-assemblies or final assemblies there is an option on the bill of materials file tab

Which allows you to include or exclude the component items from the customer orders.

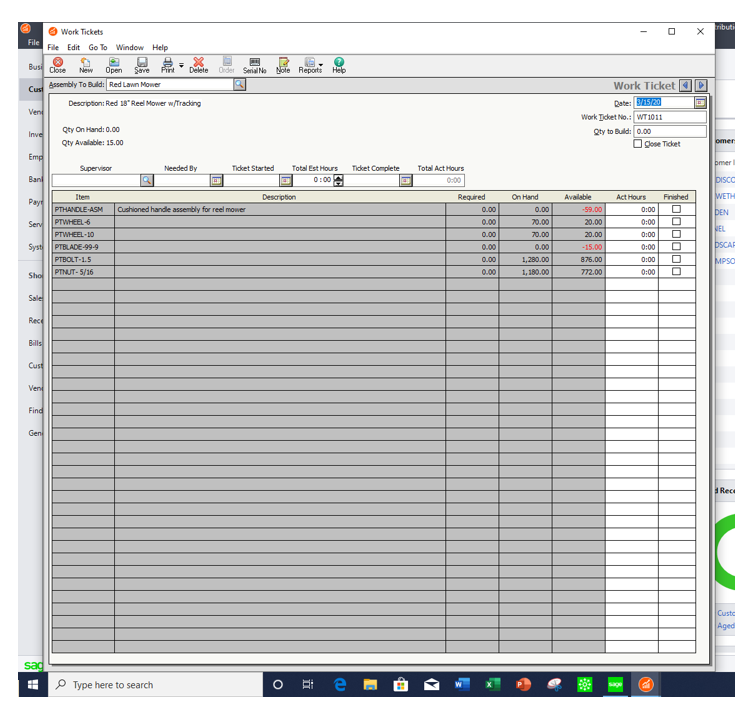

Sage 50 Bill of Material – the process to build your finished items

You can build using one of two available methods

- Option a. Assembly Build

- Found under tasks – Assemblies

- Option b. Work Tickets

- Found under tasks Work Tickets

Either of these you would need to

Step 1. Build the sub-assemblies one at a time using assemblies or work tickets

Step 2. Build the final product

This build of the final product is the step that rolls up all costs

The thing I like about work tickets is you have a printable document

Where you can add some steps to help identify the process and give direction

Then when the build is complete a document that can be provided to the front

Office to complete paperwork and invoicing

Then when you ship/invoice the final product you would have

- Reports by customer

- By item

- Sales

- Cost of Sales

- Profitability

The only item needed on the sales order or invoice is the finished item

+ any misc. items you may wish to include

I would recommend

As in any product you not allow the inventory to have quantities on hand

Go into a negative level.

I am here to help give us a call 800-475-1047

Sage 50 training and Sage 100 training for Sage Software available from Accounting Business Solutions by JCS

778 West Algonquin Road

Arlington Heights – Chicago, Illinois

Specialist in Sage Software